Laser Reflector Mirrors Front/First Surface Al/Si/Mo Coated for CO2 Laser or Scanner

Basic Info.

| Model NO. | yt891 |

| Shape | Single-lens |

| Material | Customized |

| Lenses Color | as Picture |

| Certification | RoHS |

| Customized | Customized |

| Coating | HC |

| Parallelism | <5 Arcsec |

| Transmission | >85% |

| Thickness | 1.5mm or Customized |

| Flatness | L/4 |

| Thickness Tolerance | +/-0.01mm |

| Surface Quality | 60/40, 40/20 or Better |

| Diameter | Custmized |

| Diameter Tolerance | +/-0.01 mm |

| Transport Package | Safety Green Carton |

| Origin | Changchun |

| HS Code | 9001909090 |

| Production Capacity | 40000/Year |

Packaging & Delivery

Package Size 20.00cm * 20.00cm * 20.00cm Package Gross Weight 1.000kgProduct Description

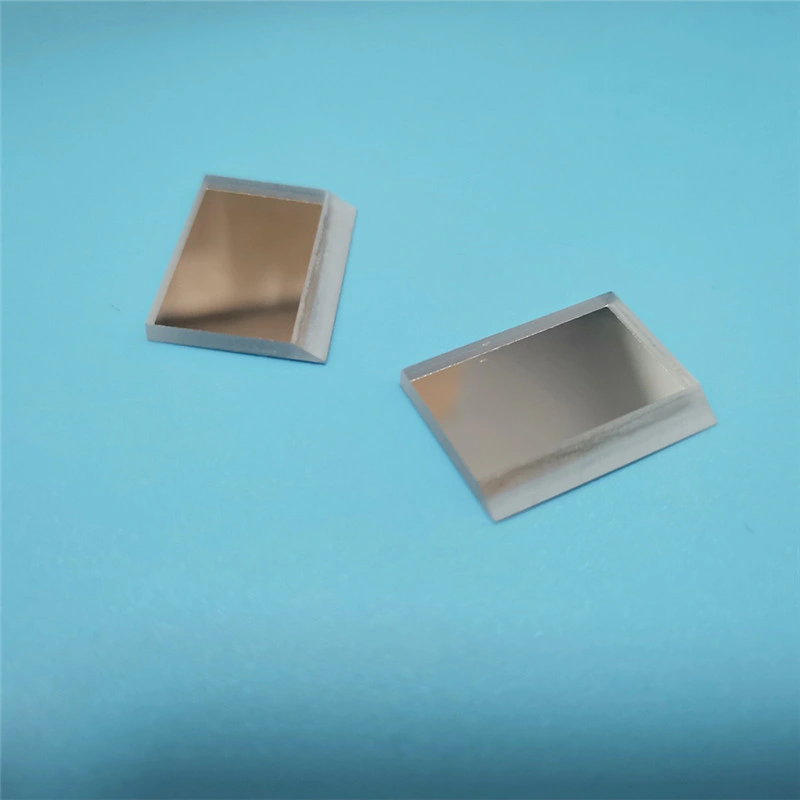

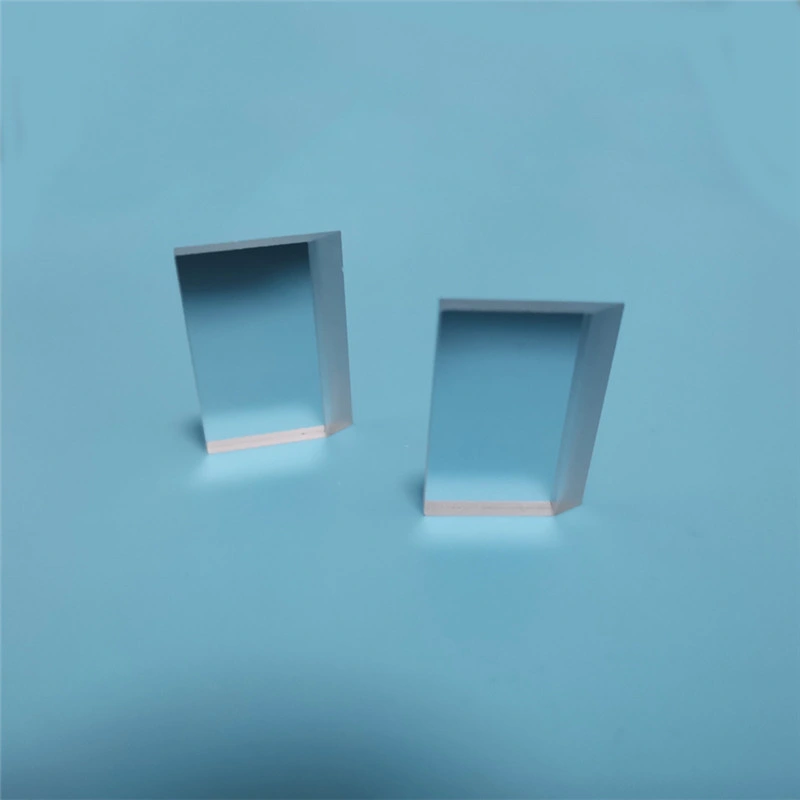

Name:Laser Reflector Mirrors Front/First Surface Al/Si/Mo Coated for CO2 Laser or Scanner

| Product Name | Laser Reflector Mirrors Front/First Surface Al/Si/Mo Coated for CO2 Laser or Scanner |

| Material | BK7,B270,fused sillicon |

| Size | customized |

| Thickness | 1.5mm or customized |

| Surface Quality | 40/20 |

| Transmission | >85% |

| Parallelism | <5 arcsec |

| flatness | L/4 |

First surface mirror

--Optical Glass first surface mirror (front surface mirror) manufactured for scientific grade reflection.

Mirrors are used for beam routing, alignment, and sampling, as well as for laser cavities. First Surface mirrors are primarily used for projecting clear sharp images in applications such as: Flight Simulation. 3D Printers. Optical Imaging & Scanning.

--A first surface mirror or front surface mirror is a mirror with the reflective

surface being above a backing, as opposed to the conventional, second surface mirror with the reflective surface behind a

transparent substrate such as glass or acrylic. In cases where the mirror is subjected to extreme cold, a polished pure beryllium

mirror is used without a first surface coating in order to obviate buckling

caused by differing coefficients of thermal expansion.

Factory information

Changchun Yutai Optics Co.,Ltd. is a manufacturer with ISO9001 certification. We are specialized in high-performance optical components include lens, mirrors, filters, windows and prisms which are specified by customers. YutaI's items are widely used in imaging, defense, medical, laser and industry market.

As a fast-growing supplier in optics, Yutai Optics has quickly established itself as a leader in optical components with advanced technology and quality control ability as Yutai aims to provide professional service and good quality items to meet customers' request. Yutai has already established long-term cooperative relation with many powerful companies all over the world.

Our Advantage

Yutai Optics has a professional sales team with excellent service. Sales team provide full service from inquiry,production,inspection,delivery and after sale guarantee. "Customer first" is sales teams goal. So Yutai always try the best to meet each customer's request.

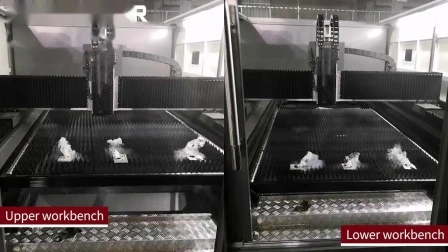

Yutai Optics processes precision optical components with many experienced engineers and advanced machines which are the important elements for the high quality items.Our advanced production machines list:Ring polishing machine,Single axis machine,Two axis machine,Four axis machine,Centering edging machine,Mechanical milling machine, Spectrograph Grinding machine,Nanotech.250upl,Talysurfi120.

Yutai Optics has a double-check inspection for optical components.The quality control department test every component carefully and provide testing report for each order. Our testing machine includes ZYGO,Stereo interferometer, Horizontal interferometer.

Process for most optics

Material-cutting-rounding-milling-grinding-polishing-edging-cleaning-coating-gluing-edging-blacking-accembly-packing-shipping

Packaging & Shipping

1 Package Detail: A. Standard carbon and envelop with plastic foam.

B. Safety green carton.

C. Customized.

2 Delivery Detail: Within 30 days.(Also depand on the quantity)

Payment: