Metal Laser Cutting Machines All The Key Transmission Parts Is Originally Imported From Germany

Metal Laser Cutting Machines All the key transmission parts is originally imported from Germany >>> Advantages 1. Fiber

Basic Info.

| Model NO. | GS-3015CE/4020CE/GS-6020CE/GS-6025CE |

| Laser Technology | Laser Control Fault Cutting |

| Control System | Optional |

| Drag Chain Tow | Import |

| Appearance Design | Glorystar |

| Working Area | 3000*1500mm and Optional |

| Laser Type | Germany Brand and China Brand |

| Laser Source | Fiber Laser |

| Transport Package | Packaged by Plywood |

| Specification | CE, SGS, FDA, Bureau, ISO |

| Trademark | GLORY STAR |

| Origin | China |

| HS Code | 8456110090 |

| Production Capacity | 3500sets/Year |

Product Description

Metal Laser Cutting Machines All the key transmission parts is originally imported from Germany

>>> Advantages

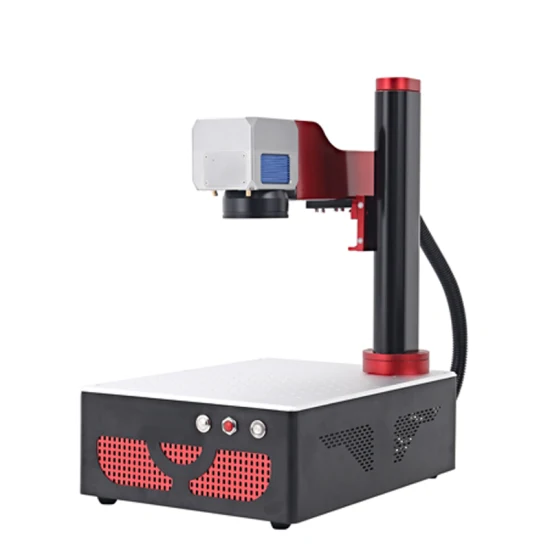

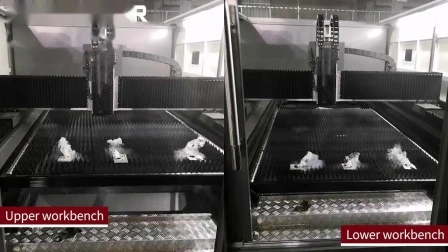

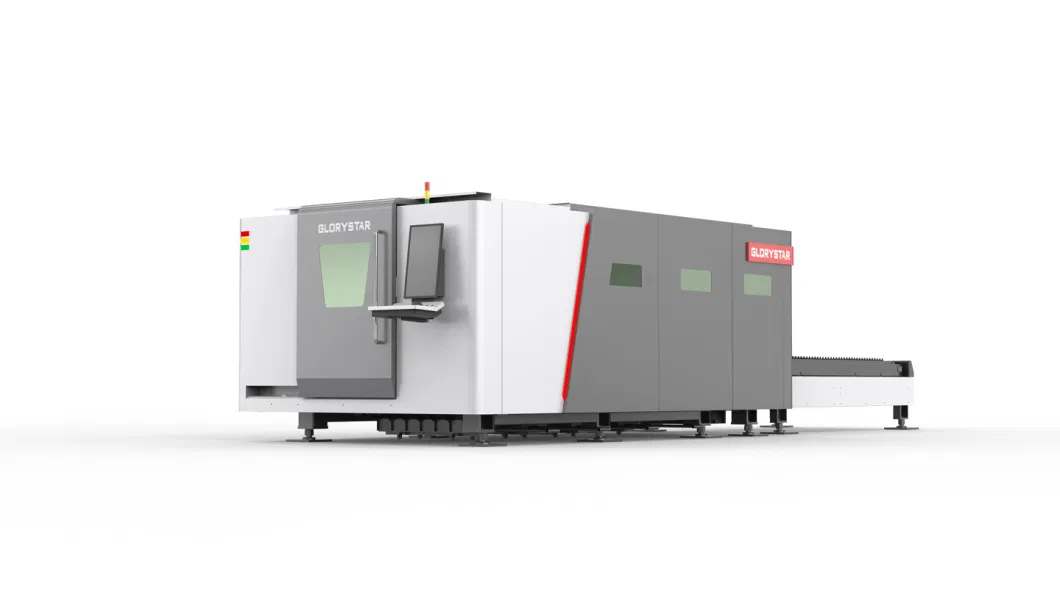

1. Fiber laser generator suitable for cutting all metal sheets.2. Gantry double drive structure and automatic exchange worktable ensure the cutting more efficient.3. Compared with YAG and CO2 laser cutting machines, fiber laser cutting machine has the processing cost advantage absolutely.4. All the key transmission parts is originally imported from Germany(gear and rack, reduction gear etc)5. Fully enclosed protective cover, generous appearance, and cut more security

>>> Product Introduction

GS-CE is the most popular mode of fiber laser cutting machine. more than 2000sets of GS fiber laser cutting machines are working in the market. GS enjoys high reputation in the market by its high quality and price ration as well as high stability and efficiency. GS enjoy the honour of well-known product in China as well some overseas market.

>>> Technical parameters

| Processing format(L/W) | 3000mmx1500mm | 4000mmx1500mm | 4000mmx2000mm | 6000mmx2000mm | 6000mmx2500mm |

| X-axis travel | 1530mm | 1530 | 2030 | 2030 | 2530 |

| Y-axis travel | 3050mm | 4050 | 4050 | 6050 | 6050 |

| Z-axis travel | 290mm | 290mm | 290mm | 290mm | 290mm |

| Precision | |||||

| Geometric positioning accuracy of X/Y axis | ≤0.05mm(full range) | ≤0.05mm(full range) | ≤0.05mm(full rangee) | ≤0.05mm(full range) | ≤0.05mm(full range) |

| Repeat position accuracy of X/Y axis | ≤0.03mm | ≤0.03mm | ≤0.03mm | ≤0.03mm | ≤0.03mm |

| The main technical parameters | |||||

| XY max. linkage positioning speed | M\MIN | 150meters /min | |||

| XY max. linkage acceleration | G | 1.8G | |||

| Position accuracy | mm | ±0.05mm | |||

| Repeat position accuracy | |||||

| Position accuracy | mm | ±0.03mm | |||

| Repeat position accuracy | |||||

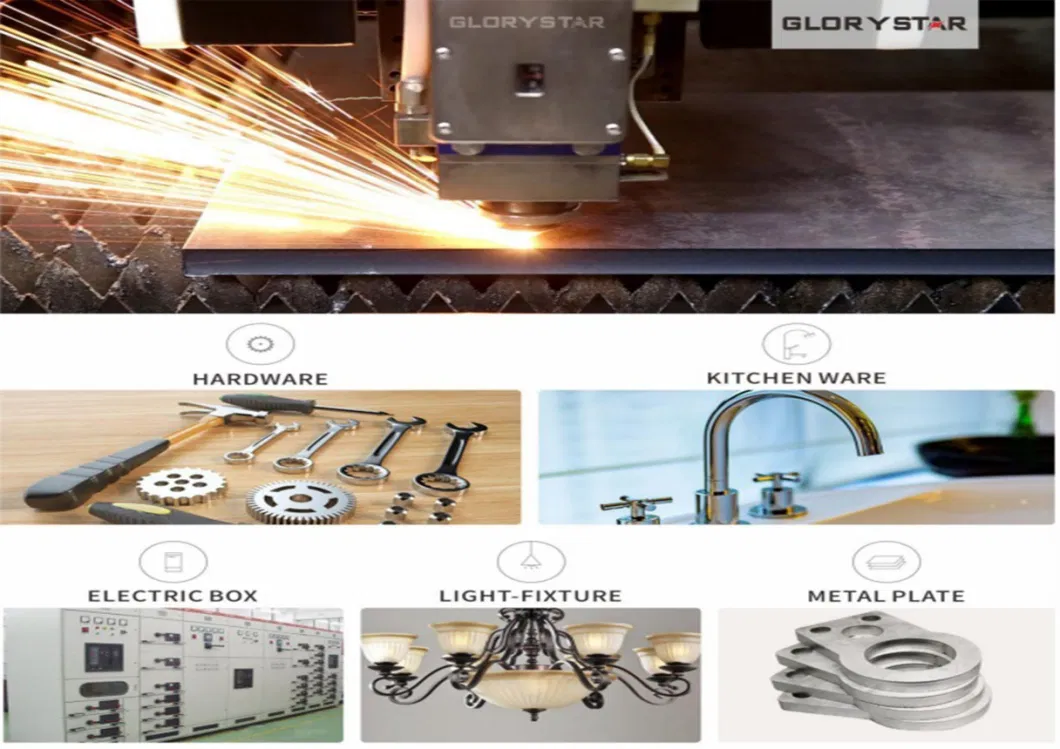

>>> Application1. Application Industries: Widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts, Nameplates, etc.2. Application Materials: Suitable for metal cutting with Stainless Steel Sheet, Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Iron Plate, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Metal Sheet,Metal Plate, Tubes and Pipes, etc.

>>> Sample>>> Quality Control and R&D

Glorystar Laser's R&D center in Dongguan is staffed by more than 60 highly skilled and experienced employees which are divided into machinery development, electrical technology, optics, software, testing, and other departments. Each department is directed by a technical leader with at least 10 years of experience in related industries. Another R&D advantage is our comprehensive strategic partnership with European laser brand European manufacture. More than 50 laser experts form Glorystar Laser and Promotec co-organized a joint R&D center to work together in the creation of high-end quality laser processing products, offering greater value for our clients.

>>> Our Factory

Glorystar Laser Adhering to the European and American technology, committed to the professional production for laser cutting, welding, marking, automatic production lines and other laser application industries, is a national high-tech enterprise integrating R & D, production and sales.The company's main products are metal laser cutting machines, non-metal laser cutting machines, laser marking machines,laser welding machines and bending machines.Products made EU CE certification and the SGS certification, and in all aspects of the incoming, process, machine, shipping and other compliance with ISO quality and environmental management system management guidelines to ensure that the national quality.

>>> Honors

>>> After-sale ServiceInstallation and debugging Technicians can be sent to the factory for training (free of service fee for the first time). Customers only need to provide accommodation for engineers. Training Free of charge for training within warranty. But customers need to take charge of the cost for accommodation, air tickets, visa fee. 24/7 online service All our laser equipment is provided with 12 months warranty. Glorystar Laser offers free maintenance or replacement service if something is wrong with the equipment under warranty. If it is out of warranty,Glorystar Laser will send engineers to your factory as soon as possible and only charge the cost of parts. Accessories supply IPG laser source is 2 years. Other parts is one year except for optical and consumable parts. Prolong serve is always available for option. Free of charge for fixing and changing parts within warranty. Only changing parts , the freight should be charged by customers. Remote diagnosis Glorystar Laser can check the running status of the customer's laser cutter through our remote maintenance system. Our technicians can perform troubleshooting via remote access instead of on-site diagnosis and maintenance, saving you a lot of time.

Additionally, Glorystar Laser will establish a special user profile for all customers who have purchased equipment from us to record your usage, maintenance records and other information. This will help us to learn about customer information more quickly and thus provide necessary upgrades according to customer feedback

Welcome inquiry, our business staff will provide you with warm service, enquiry hotline

Send to us