High

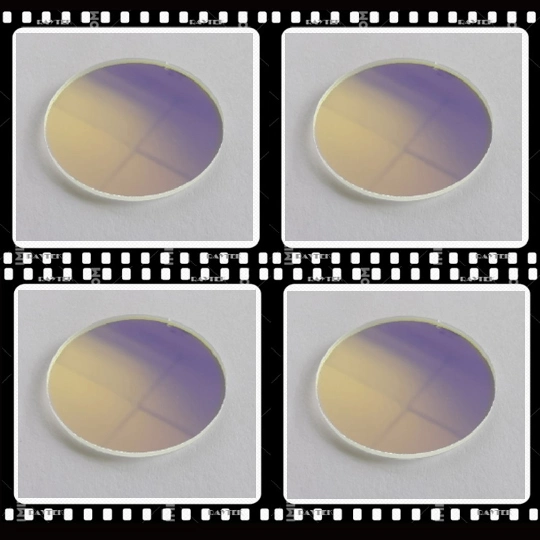

General Introduction: Raytek's high energy Nd: YAG laser 50/50 splitter is made of high purity fused silica substrate an

Basic Info.

| Model NO. | RAY-OB083# |

| Wavelength Range | 266nm/355nm/532nm/1064nm,or Other |

| Antireflection Coating | Hbs.11p/Hbs.11s/Hbs.13p/Hbs.13s Hbs.27p/Hbs.27s/Hb |

| Surface Flatness | Less Than Lambda/10 at 632.8nm |

| Surface Quality | 10-5 Scratch-Dig |

| Substrate | UV Grade Fused Silica |

| Transport Package | Cartons or Wood Case |

| Specification | 10.0mm/12.5mm/25.0mm/30.0mm/40.0mm/50.0mm |

| Trademark | Raytek |

| Origin | China |

| HS Code | 9002909090 |

| Production Capacity | 100000PCS Per Year |

Product Description

General Introduction: Raytek's high energy Nd: YAG laser 50/50 splitter is made of high purity fused silica substrate and superhard dielectric coating. After relevant testing and certification, the beam splitter can withstand high energy pulse with high damage threshold..Products Name: High-Energy Nd:YAG Laser Beamsplitters Alias: Laser Line Plate Beamsplitters,Laser Plate Beamsplitters, Laser Line Plate Beam splitters, Laser plate beamsplitters, Laser beam splitter plate, Nd:YAG Laser Beamsplitters, High-Energy Laser Beamsplitters, etcBandpass Filters Substrates:UV Grade Fused Silica| Optional I: | UV Grade Fused Silicafrom CORNING, OHARA, SCHOTT, LEONI, AGC,HELLMA, NIKON,VITRON,ETC |

| Optional II: | Equivalent UV Grade Fused SilicaMade in China, C-laser own brands |

Main Applying:

| Applying Fields I: | Parallel transmission of information and energy in laser communication, optical storage, optical interconnection, laser 3D imaging, laser processing and other fields. |

| Applying Fields II: | In laser communication, multi-channel parallel transmission of fan out and lidar multi-point parallel transmitting antenna is proposed;In laser processing, the two-dimensional multi-point laser drilling, laser marking, fast multi-point parallel 3D laser printing, as well as the multi-point array laser spot removing and laser skin rejuvenation in laser micro invasive medical and beauty treatment. |

| ***** |

Main Characters:1).Designed for Nd:YAG laser fundamental and harmonics2).Equal 50/50 (R/T) beam split for S or P polarization3).Low wavefront distortion4).Hard refractory coatings for high damage threshold5).10-5 scratch-dig surface quality6).AR coated back surface eliminates ghosting7).Versatile Coating Options8).UV Fused Silica Substrate9).Slight Wedge Suppresses Unwanted Fringes10).High Damage Threshold11).Reflectance Outside the Design WavelengthsProducts Highlights:1).Different grades materials for option.2).High precision & high surface roughness;3).Sizes can be customized as per the customers' request4).Quick lead time and delivery time.5).Matching super optics custom and processing capacity, including Moulding, CNC machining, Polishing, Particle beam processing, Magnetic flux conversion processing, Grinding, Coating, Lightweighting, Custom Shaping, Counterbores, Drilling & Coring, Edge & Bevel Polishing,3D Contouring, Bevels & Chamfers, Steps & Slots, Laser Cutting & Marking, Metrology & Inspection, Precision Pitch Polishing, Double-Sided Polishing, Optical Assembly, Measuring, etc.6).Excellent post-sale quality warranty, with "3R"-return, replace & refund policyMain Optical Tech Specification:

| Tech Data | Description |

| Type | Plate Beam splitters |

| Material | UV Grade Fused Silica |

| Coating Type | HBS.11P/HBS.11S/HBS.13P/HBS.13SHBS.27P/HBS.27S/HBS.33P/HBS.33S |

| Antireflection Coating | V-coat AR, R <0.5% |

| Surface Quality | 10-5 scratch-dig |

| Surface Flatness | ≤λ/10 at 632.8 nm over the clear aperture |

| Extinction Ratio | - |

| Wavefront Distortion | - |

| Angle of Incidence | 45°±3° |

| Damage Threshold | 0.25 MW/cm2 CW, 2.5 J/cm2 with 10 nsec pulses at 266 nm, typical |

| Orientation | - |

| Reflection | - |

| Reflected Beam Deviation | - |

| Transmission | - |

| Transmitted Beam Deviation | - |

| Clear Aperture | > central 85% of diameter |

| Polarization | - |

| Operating Temperature Range | - |

| Parallelism(Wedge) | 30 ±15 arc min |

| Chamfers | 0.25-0.76 mm face width |

| Chamfers Angle Tolerance | 45° ±15° |

| Durability | MIL-C-675C, moderate abrasion million cycles |

Popular Physical Size Specification:

| Size | 25.4mm/50.8mm orDesign & custom manufacturing as per demand. |

| Size Tolerance | +0/-0.13 mm |

| Thickness | Design and custom as per demand |

| Thickness Tolerance | ±0.38 mm |

| Wavelength Range | 266nm/355nm/532nm/1064nm,or other |

Main Cooperation Materials Manufacturers: CORNING, OHARA, SCHOTT, LEONI, AGC,HELLMA, NIKON,VITRON,C-LASER,ETCMain Export Countries & Areas: Usa, Uk, Japan, Germany, Spain, France, Swiss, Korea, Russia, Pakistan, India, Portugal, Canada, New Zealand, Australia, Saudi Arab, Turkey, Finland, Poland ,etc.Raytekoptics Extra value added services offered:1). Optical workcraft & process solution design;2). Rough processing raw materials;3). Semi finishing raw materials;4). Fabricate custom sizes and shapes;5). Design and supply custom coatings;6). Modify and resurface customer supplied materials;7). Drill holes, notch glass and provide beveled substrates;8). Precision polish optics with non-standard aspect ratios;Payment Method: by T/T or Western Union.Delivery time: 7-10 days. Quality Warranty: Ruitaiphotoelectric(Raytekoptics) offers quality warranty for our optics products with "3R" policy. For any inferior-quality products, Ruitaiphotoelectric(Raytekoptics) is responsible for return, replacement and refund.

Send to us